How To Make A Miter Gauge For Table Saw

Miter saw gauges confuse a lot of finish carpenters for one simple reason—they aren't designed for terminate carpentry, they're designed for framing and stairs. Let me prove y'all what I hateful.

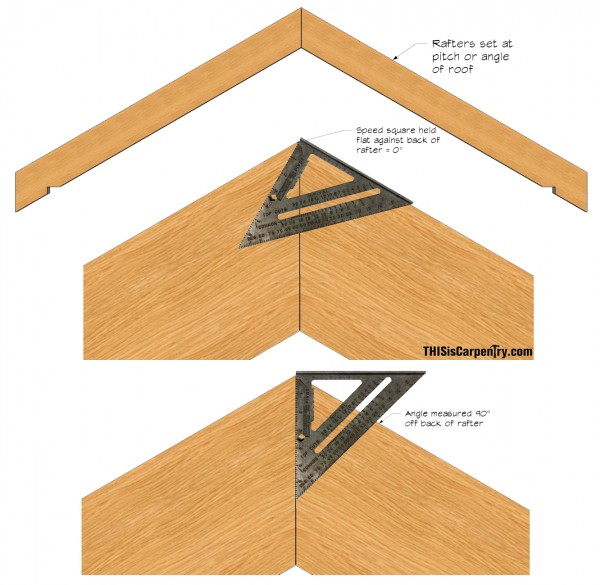

When a framer builds a roof, they beginning establish the PITCH of the roof—4/12 or 6/12. That pitch is the angle the rafters follow. All of the cuts made to that rafter—the ridge cut, the plumb cut, and the birdsmouth are all measured off the BACK of the rafter—off 90 degrees to the angle of the roof.

(Notation: Click any image to enlarge.)

That's why virtually miter saw gauges are set up up off 90 degrees to the back of the contend! In fact, some miter saws even include roof pitch angles on the miter saw gauge.

Just those angles just confuse cease carpenters. Finish carpenters are always bisecting corner angles—which is like shooting fish in a barrel to do with a protractor.

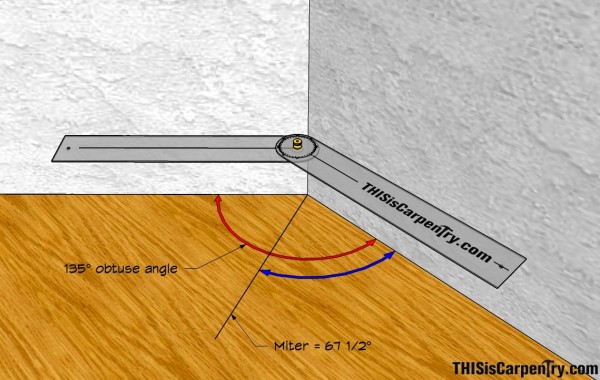

A 135 degrees angle looks like this:

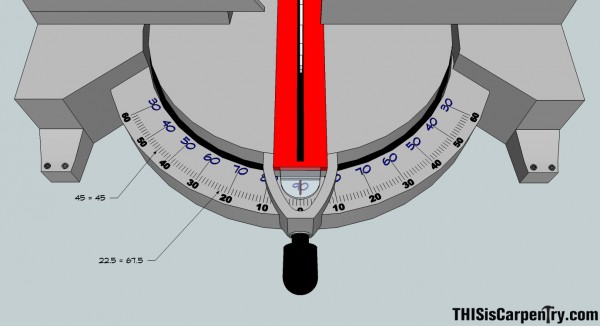

A 135 degree bending is an OBTUSE bending. The miter for this corner is 67 1/2 degrees. That's easy to cut on your miter saw. Just set the saw at 22 1/2!

Only the angles on a miter saw gauge are off 90 degrees to the angles on a protractor, which causes a lot of confusion. Some carpenters opt to use a Starrett Protractor. But I prefer to have the guys on my crew utilize a standard protractor, so they'll know at a glance the deviation between an acute angle and an obtuse angle. That means when they visualize the miter, they'll be starting off on the right foot!

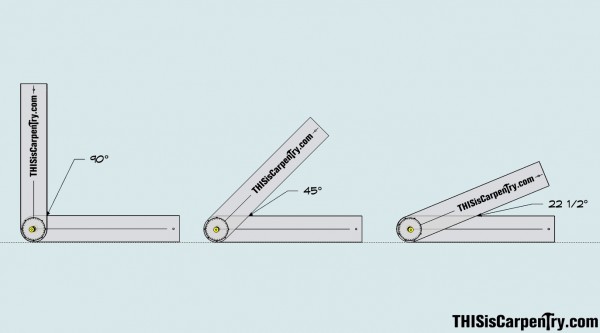

A 22 one/ii degrees angle is an Acute angle. You can't cut that miter on a miter saw without an acute bending jig.

| Miter saws didn't e'er come with miter saw gauges that were set xc degrees off from protractors. Dorsum before framers used miter saws, finish carpenters could use a protractor to read corner angles without any confusion. |

The easiest way to solve this whole problem is to employ a Sharpie to mark your miter saw gauge with protractor numbers.

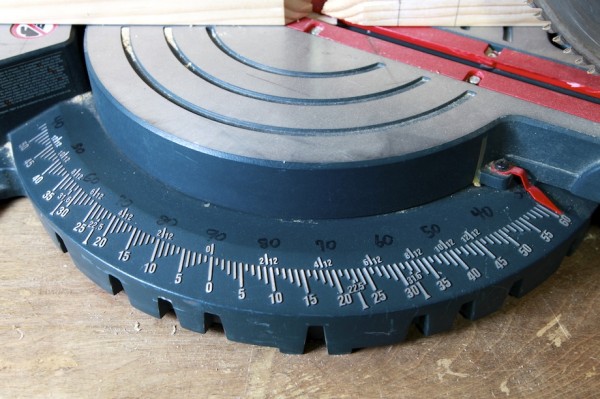

In fact, some manufacturers include protractor angles on power miter saws:

I just wish they all did!!!

• • •

Author BIO

More recently, he has focused on high-end finish carpentry. He is currently a Projection Manager at Millworks By Design, a finish carpentry company located in Agoura Hills, CA.

Jesper enjoys SCUBA diving, mountain biking, and especially photography, which he practices in his free fourth dimension. Recently married, he and his wife, Julia, spend their vacations traveling Europe and visiting castles, museums, and other historical sites. He often draws inspiration for his finish carpentry work from classical architectural details that he has photographed in cities throughout Europe, such as Paris, Rome, and Seville.

Source: https://www.thisiscarpentry.com/2011/07/29/miter-angles-miter-saws/

Posted by: meffordberldn60.blogspot.com

0 Response to "How To Make A Miter Gauge For Table Saw"

Post a Comment